Optical metrology, metrology equipment

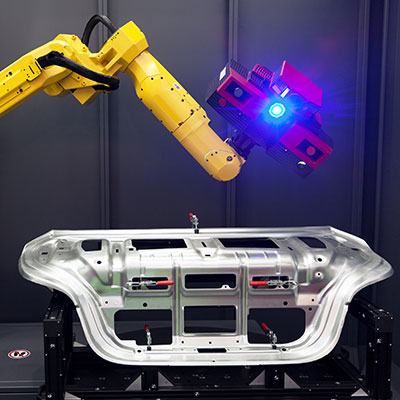

In contrast to tactile metrology, optical metrology contactless scans the object under test using light. Optical metrology methods are used for quality control and also to detect e.g. shapes for 3D printing. Optical 3D metrology is used to verify compliance with geometrical dimensions of components, and it can now in many cases replace previously employed tactile measurements that rely on mechanical gauges or coordinate measurement machinery. Optical metrology includes measurement methods, measurement systems, and measurement methods that rely on light to determine physical variables or to directly determine properties of light.

Interferometry

Interferometry is a measurement method that relies on the phenomenon of wave interference. Measurements can include certain characteristic data of the waves and of the materials with which the waves interact. By using two light beams, an interference pattern can be formed when the two beams overlap.

Because the wave length of visible light is very short, small changes of the deviations in the optical paths between the two beams can be detected. Optical interferometry has therefore been a valuable measurement method for more than one-hundred years.

Optical 3D measurement methods

Optical 3D measurement methods are now widespread.

A wide range of methods are used, depending on the application. Optical sensor systems for 3D measurement methods generally consist of a light source that illuminates the object under test with a special-purpose, known light signal, and of a receiver that records the light signal. The object now changes the amplitude, phase, polarization, or direction of the optical signal in a known manner, which is then used as a metrological parameter. By analyzing this change, and depending on the measurement principle, the 3D information or surface texture of the object can then be inferred.

You can count on B&M Optik as your source for a wide product range for the various optical metrology methods.