The highly specialized top event for all those involved in the exploration of light is in full preparation: The 16th Optatec - international trade…

Good is not good enough as long as there is a better way.

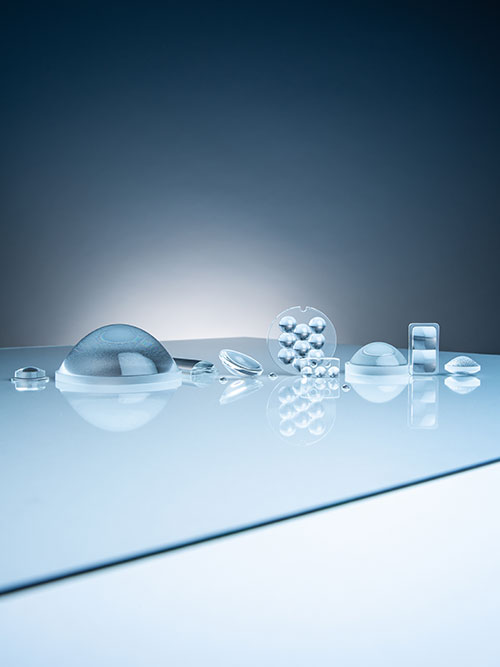

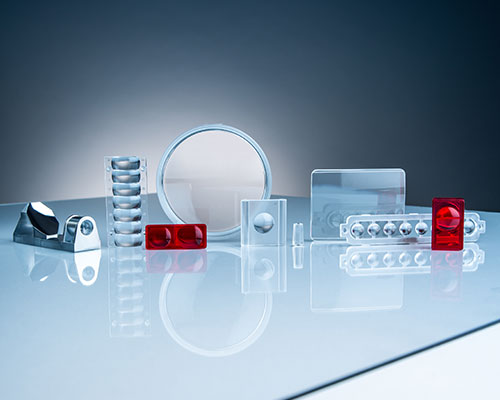

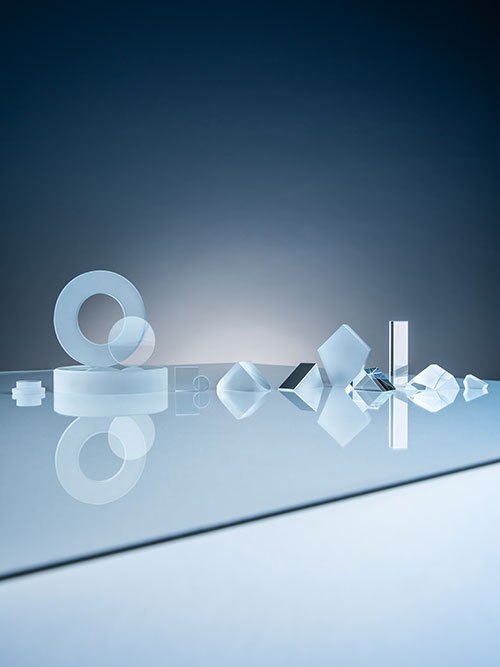

B&M Optik GmbH is a mid-sized business headquartered in Limburg an der Lahn (Hessen). Since being incorporated, we have developed an outstanding reputation as a reliable and trusted manufacturer and partner for optical assembly elements and components. As an owner-operated business with tradition and experience, we know how important it is to respond to customer requirements individually. This is why we place a top priority on cultivating the collaboration with our customers.

We also provide the best-possible quality in everything we do - from the product to customized consulting and ending with short response times for solutions to problems. Our day-to-day objective is to repeatedly exceed these expectations, entirely to the benefit of our customers. You too should get to know our innovative products, technologies, and expertise. We will gladly support you during the development phase of your product. We believe that the sooner we can work hand-in-hand, the faster we can found a solution that meets your engineering and commercial needs.

Customized solutions that meet your exact needs

We look forward to demonstrate our capabilities to you. As long as there is a better way, “good enough” simply will not do for us. And our customer gets a sense of this every day.

![[Translate to Englisch:] Filter [Translate to Englisch:] Filter](/fileadmin/bmoptik/images/uebersichten/filter.jpg)